From speedy installs and airtight seals to creative, new applications, the benefits of keder remain key to industry progress.

Hidden within aluminum extrusions, shaping both simple tents and extravagant clearspans, lies the years-old invention that continues to help advance the success and technology of the tent industry today: keder, a bead or core that attaches to a fabric panel and then slides into a corresponding track in a frame.

“Keder makes a joint, essentially, between two pieces of vinyl that you join using an aluminum track,” explains Nelson Grandchamp, production manager at Grandchamp Structure Design in Repentigny, Quebec. “You don’t usually see it, but we couldn’t have the tents we do today without it.”

A revolutionary solution

Earlier methods for joining panels included lacing adjacent sections with corresponding loops and grommets to mechanical fasteners, such as metal clips or plastic side-release buckles, Bryan Bolt, sales manager at Moore, S.C.-based Top Tec Event Tents, explains in a whitepaper he authored on the basics of keder.

Whether installers connected the pieces on the ground or after placing the fabric on top of the frame, the process was cumbersome and somewhat dangerous, as it required extra time on a ladder, he says. Dragging the tops over the frames also shortened the life of the fabric.

he says. “It just makes for a really easy and fast installation.” Photo courtesy of Grandchamp Structure Design.

When a better process was realized, there was no looking back. “The concept of keder is not new, although I didn’t hear that term until probably the mid-90s,” says David MacArthur, national sales manager at Losberger De Boer in Frederick, Md. “The Europeans have been using it since at least the late 70s, and the things that we in the United States learned from them were incredible. We didn’t realize how effective it could be and it really took off.”

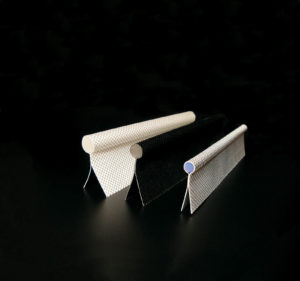

Today, keder is used in several industries for almost any application that requires fabric to be attached to a frame. The product consists of a flexible PVC core (also called a bead) wrapped in fabric that has exposed fibers on the outside, allowing the keder to glide into an extrusion with a corresponding keder track.

“Basically, you’ve got a vinyl panel that has a raised bead across the edge of it. That bead slides into a track of the framework, so the framework has to be specific to accept that bead,” Bolt says, noting that many sizes are available but commonly range from 11 to 13 millimeters.

“You can order keder in several ways,” MacArthur explains: “You can get just the raw bead and manufacture the keder yourself by wrapping it with webbing or vinyl and welding it, or you can order premanufactured keder that’s already welded onto the webbing, which then just separates and attaches to the fabric.”

Losberger orders keder in bulk rolls, using thousands of feet every year, MacArthur says. Grandchamp depends on software to measure how much keder to order and how many aluminum beams the company needs, says Grandchamp. “It comes in a giant spool, so we just cut what we need,” he says. Because of this, minimal waste exists.

Keder can be attached to fabric in multiple ways. “I have customers that hot weld, RF weld and sew it to their different fabrics, so it’s pretty easy for the customer to install,” says Keith Eismann, vice president of Keder Solutions in Milwaukee, Wis.

Grandchamp says his company first used hot air welding as an affordable solution but switched to RF welding for a “nicer, stronger finish.”

Faster, tighter, stronger

Using keder, tent fabric can be installed over and around “just about anything imaginable, often times without even getting on a ladder,” Bolt says. Top panels provide attachment points for pull ropes, which stretch over the frame and slide the keder through tracks in the frame rafters when pulled from the opposite side of the roof framework, he explains. The tops glide over the frame and are attached by a fastening system along the perimeter. “The keder’s engagement in the framework seals out the elements, making for a supremely tight fit.”

Sidewalls can also be built with keder on up to three sides, engaged in the legs as the tops are engaged in the rafters.

“Keder is air- and watertight and a great way to break down big pieces of vinyl,” Grandchamp says. “You buy a tent to protect you from the weather, and keder is the solution for that.”

To get a tight seal, Bolt recommends tensioning the main rafters, which are at all of the keder locations around the tent, before doing any other buckles, so those get primary tension. “They’re structural elements, so we put a lot of tension on the keder to make sure the tent is nice and tight,” he says.

Though its use is well-known, Eismann wishes more people realized how much keder improves the installation process. “It’s a seamless product,” he says. “From water not leaking in to light not getting in, it is so much easier to use and creates a much cleaner look than grommets or metal clips.”

Bolt believes a factor keeping more people from using the product is its price tag, but that way of thinking doesn’t consider labor dollars. “The parts are a little more expensive, but the installer recoups that money so much faster because of how much easier it is to install and how much longer the tops last. There’s a lot that the system will allow you to do that you could never do with a loop and grommet tent.”

He recalls using keder to install a 40-by-100-foot tent in less than four hours for a client who was spending nearly all day doing the same work without it. “It was all because of what the system can do, and he was blown away,” Bolt says.

Caution: Care required

Valuable as it may be, keder is not immune to maintenance issues. Normal wear and tear is common, so repairs are inevitable. “Keder will typically tear along the rafter where the keder bead is along the perimeter of the tent. Usually that happens when the installer is not pulling parallel with the keder rafter,” Bolt says.

Eismann also reminds installers to ensure the framework is clear of debris or damage before sliding the keder into it, as any nicks or cuts can tear the keder. “The end user maintaining their inventory of aluminum will make the installation of keder a breeze,” he says.

The manufacturer also plays a role in a smooth installation process. “People in the field depend on high-quality manufacturing,” MacArthur says. “The manufacturer is responsible for ensuring that the fabric sections sent out with the tent are cut precisely so the keder slides right into the channels. If a section of fabric you’re putting in between beams is too narrow, you won’t be able to get them in. If it’s cut too wide, you have a floppy roof section.”

Repair keder systems are available from keder product manufacturers. Another easy option to repair torn keder fabric is to, as MacArthur says, “just cut it off and re-weld it on.”

Creative concepts

While the purpose of this revolutionary product has not changed since its inception, innovative techniques and applications are being developed. “Rental companies are finding new ways to incorporate it into their installs,” Eismann says. “They’re using it on such things as rain gutters and door surrounds and even for hanging lights in their tents.”

“Where I’ve seen it change is in the attachments that fit into keder slots at the tops of sidewalls,” Bolt says. “Most of the bigger manufacturers are integrating those keder slots into several places within their frameworks. It’s not just for the tops anymore. It’s for the sidewalls, it’s for the legs of the sidewalls and across the tops of the sidewalls.”

TopTec, for instance, offers a sidewall called a slider wall. It opens and closes like a curtain because it’s suspended from the keder rail along the perimeter of the tent—something that couldn’t be done with a regular clip-on type wall.

Partitions are another example. “To put a partition in a tent, it’s very easy to run a keder up through a bottom channel,” MacArthur says. “The top channel is already taken because of the roof cover in there, but two more channels on each beam are below the roof covers and those can be used to slide in keder that’s attached to tent partitions.” He’s also used it to hang liners or add insulation.

Pole tent manufacturers have found hybrid ways to use keder as well, MacArthur says, by putting keder in their side poles and putting a separate sidewall in between each side pole instead of running a long length of sidewall.

Keder use is “growing for sure,” Eismann says. “The more people learn about keder, the more uses they find for it. I have customers that regularly want to convert their standard frame tent into a kedered frame tent so they can gain efficiencies for their installers. Once someone understands the benefits of using keder, they find more projects and products to use it on.”

“The role that keder plays is critical to our business,” MacArthur adds. “Without keder, we don’t have clearspans. It’s indispensable.”

Holly Eamon is an editor and writer based in Minneapolis, Minn.

Keder is most commonly used to attach roof panels, but manufacturers and installers are finding new ways to incorporate it into their builds. “Keder provides a lot of opportunities for creative use of fabric,” says David MacArthur, national sales manager at Losberger De Boer in Frederick, Md, “from creating partitions and rain gutters to attaching roof covers, cable end covers and sidewalls.”

Keder is most commonly used to attach roof panels, but manufacturers and installers are finding new ways to incorporate it into their builds. “Keder provides a lot of opportunities for creative use of fabric,” says David MacArthur, national sales manager at Losberger De Boer in Frederick, Md, “from creating partitions and rain gutters to attaching roof covers, cable end covers and sidewalls.”

Bryan Bolt, sales manager at Moore, S.C.-based TopTec Event Tents is seeing more attachments, such as lighting accessories, designed to fit into the keder slots. “It’s not just for the tops anymore,” he says. “It’s for the sidewalls: up the legs and across the tops of them.”

Applications include:

- Rain gutters: Keder can be used to form a gutter to prevent rain runoff from dropping down between two tents standing next to each other.

- Liners and insulation: One of Losberger’s frame profile designs separates the keder channels by 200 millimeters, which creates an opportunity to do an installation that has two roof covers with 200 mm of dead air space. The space can be filled with insulation or decorative liners.

- Platforms: If a tent is installed on uneven ground, a platform helps to level it. “You can put a kedered piece of railing from one base plate to the next all around the perimeter of the tent,” MacArthur says.

- Double keder: For a few of its products, Losberger puts two keders in one channel to attach fabric around the perimeter of a tent when building a frame with a high center peak.

TEXTILES.ORG

TEXTILES.ORG