From cattle to casinos to rental cars, radio frequency identification or RFID technology is making inroads across a myriad of industries, including the tent industry, as manufacturers and event rental companies turn to RFID tags to streamline production and help manage inventory.

According to Mathieu De Backer, vice president of innovation and sustainability with Avery Dennison Smartrac in Ascoli Piceno, Italy, current RFID technology is particularly prevalent in retail distribution channels and in-store product tags.

“Walmart, the world’s largest retailer, has mandated that its suppliers use RFID across a range of product lines so it can track goods in transit, in its warehouses and in its stores,” De Backer says. But its use goes way beyond retail. Car manufacturers use RFID tags to track millions of components in their warehouses. It’s also being incorporated into car tires so that safety features can be embedded and fitting errors reduced. And the pharmaceutical industry uses it to track medications and ensure the integrity of ingredients.

Within the tent industry, RFID tags are making a big impact. According to Darren Morizet, founder and CEO at Easy RFID Pro in Poughquag, N.Y., RFID tags are commonly installed in tents, sidewalls, inflatable attractions, linens and lounge furniture.

Types of RFID

Generally speaking, there are two types of RFID systems. The first is a fixed RFID system. As Morizet explains, this requires hardware to be installed throughout a facility and can be costly to implement. The other option is a mobile solution, which generally comes at a reduced cost and can be used both on and off premises.

“There are also two different types of tags. Active tags are more expensive and require a battery to work,” Morizet says. “They offer extended read ranges and the possibility of real-time tracking. The other type of tag is a passive tag. These tags are much less expensive, lightweight and do not require a battery.” They do, however, come with limited range and are more susceptible to interference. Passive tags are more commonly used for tents and textile fabrics and are best suited for many types of inventory management.

De Backer further explains the two main types of RFID. Ultra-high frequency (UHF) are long range tags that are used in warehouses, logistics, distribution centers and retail stores. These are read by special readers and can tell operators exactly how many products they have on hand.

“Near field communication [NFC] is an RFID variant we are all familiar with since it enables contactless payments via card and also Apple and Google Pay,” De Backer says. “However, this technology can also be used to introduce interactive elements to products—consumers simply use their phone in the vicinity of the item to find out more, view videos or enter competitions. We can expect to see ‘tap to find out more’ increasingly used by brands across a range of items.”

The choice of RFID technology depends on the specific requirements of the application. Although metal will not allow the signal to transmit through, PVC, vinyl and fabrics are very well suited to allow RF energy to pass through. Morizet says that it should be noted that read ranges may also be affected, depending on the type of tag used for a certain application.

“It’s a lot of trial and error to find the right tag and antenna design that works for a specific application while trying to achieve maximum read distance,” Morizet says. Tag orientation is another factor that requires thought in some cases.

Avery Dennison also has developed AD TexTrace™ technology, which enables RFID functionality to be embedded into custom-made woven or knitted inlays, which can then be sewn onto or inserted into products. This creates opportunities to extend the value of RFID beyond the point of sale.

“Brands and retailers can use these discreet inlays to fulfill many value-added business processes simultaneously, as they offer improved inventory management, while enhancing and digitizing loss-prevention systems and electronic article surveillance,” De Backer says.

Preparing for the future

Fred Tracy, owner of Fred’s Tents and Canopies Inc. in Waterford, N.Y., has dabbled in incorporating RFID technology into his company’s products for the last five to 10 years. He began by researching the use of RFID tags within the cattle industry, recognizing the potential use of similar tags within the tent industry.

“The new tags are miles ahead of where they were just five years ago,” Tracy says. “And I think the tags in two years will be further ahead of where they are now. We’ve always had people ask us, ‘How can we save time, energy and effort?’ So we’ve looked at systems of how we can save our customers’ time and money—in either picking the product, creating the product, claiming the product or running it through their systems.” And that’s where the idea of incorporating RFID tags into all of Fred’s Tents’ products came in.

“We made a commitment in 2023 and said that we’re going to put it in all of our top fabric, regardless of if you have a reader or not,” he says. “If you buy one in the next year or in the next five years, the RFID tag will be in there.” Indeed, Fred’s Tents is the first major tent manufacturer to make the commitment of embedding RFID technology within 100% of its tent tops and roof panels.

“The feedback has been positive, as two national rental companies have signed up for the program,” Tracy says. “As your inventory gets older or ages out, we’re saving you the time of sending it back to manufacturer or even putting the tags in personally or paying the staff to go back through and insert these tags. The tags and readers will continue to improve as more people jump on board.”

The specific RFID tags Tracy uses do not require a battery. Rather, the RFID reader energizes the tag, allowing it to send back a signal to the reader.

“In five, six or seven years down the road, the tag will still be functional,” Tracy says. And because the tag is encapsulated into the fabric, it is not exposed to the elements and is protected during the cleaning process.

Small, but powerful

The tag that Fred’s Tents is currently using is practically invisible—about the size of a piece of Trident gum. This is obviously an important detail in an industry where aesthetics are everything. Yet despite its size, even when a tent is folded up in a bag, the tag installed on it can still be read.

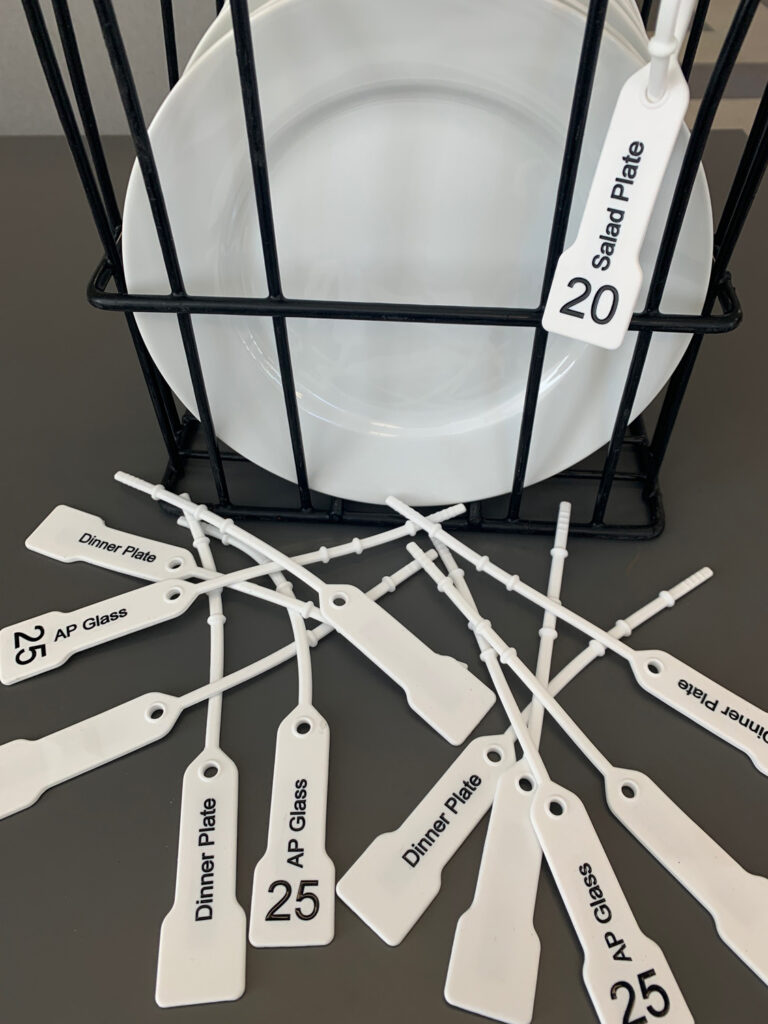

Indeed, in almost all cases, RFID tags can be placed inside something else to work for a specific application. For example, Morizet says placing an RFID tag on linens could be any of the following.

A silicone RFID tag can be placed inside a polyester pouch and then sewn onto the linen much like a size label. Another option would be tags with adhesive or button tags.

For tents, many people will place the tag between two pieces of vinyl and seal it there using an RF weld, heat weld or chemical weld or they will just sew it closed. For existing inventory, if the tent has a pocket-welded flame certificate, you can make a small cut in the first layer of the certificate, slide the tag inside, and then seal it closed using any of the above methods.

“The easiest and quickest process for many tent companies is to use repair vinyl that has an adhesive back,” Morizet says. “This works well but the patch needs to be sized and adhered well, as per the manufacturer’s instructions, or it will come off in a tent washer.”

Another important development of using RFID within the textile industry is that by placing a RFID tag on a piece of tent canvas or on a couch cushion, for example, it allows the user to access the entire history of that item.

“For example, how many times has it been washed? How many times has it been repaired? When was the first time it was put into service? How many times has it been rented to a customer?” Morizet says. “These are just a few examples of all the data that can be tracked.”

Morizet says perhaps the biggest “wow” factor for most people who deploy this technology is the ability to locate an item. Much like how a metal detector works on a beach, you can select the item or items you’re looking for, walk down your warehouse aisle, and as you get closer to it, the sound will beep faster and faster directing you to within inches of the item.

“This is particularly helpful when you have multiple tents in your wash bay and are trying to find one specific item quickly,” Morizet says, “or when you’re loading a truck and you just can’t find a custom-fabricated piece that you do not use very often.”

Common misperceptions

One of the common misunderstandings regarding RFID technology is its “read distance.” As Morizet explains, it is often thought that you can read RFID tags from a very long distance.

“While it’s possible to read active tags with special equipment at long distances, it’s just not practical for our industry,” Morizet says. “It’s more common that you would read distances in the one-to-three-meter range with a mobile solution.”

In addition, many people think they can install an RFID tag on a tent pole. While this is possible, the practical use with this technology just doesn’t work. Here’s why: The minute you stack another pole in front of that tag, it becomes unreadable.

“The beauty of the technology is that we do not need line of sight to read a tag, which means we can read multiple tags very quickly and do not need to see the tag in order to be able to read it,” Morizet says. “You can read tags through many types of materials including vinyl, polyester, wood, plastic and many more.” However, while you can read an RFID tag when placed on metal, you cannot read a tag through metal.

There are many types of RFID tags that work very well for the many types of products that are used in the tent industry. Morizet’s personal favorite are silicone-encased tags.

“These tags work well with many cleaning chemicals, hot water and, of course, in commercial tent washers,” Morizet says. “There is most certainly a tag for any application you will need in the world of RFID.”

Continuous evolution

RFID is not a new technology, having been around for many years. Morizet points out that the biggest challenges have been the cost of equipment, the expertise needed, time to implement, and most important, the software to tie everything together so that it works with the needs of event rental companies.

“In the past, RFID software always had to be adapted to work instead of being designed from the ground floor up for the needs of tent rental companies,” Morizet says. “As the hardware and software technology is improving and other options such as mobile solutions are hitting the marketplace, the cost to implement RFID has dropped significantly.”

As a growing number of companies and industries adopt this technology, it can offer incredible improvements to operating efficiency. “Imagine a tent not only telling you where it is but that it’s wet or covered in mold without any input from an employee,” Morizet says. “We’re not completely there yet, but it is certainly possible in the future.”

Maura Keller is a freelance writer based in Minneapolis, Minn.

TEXTILES.ORG

TEXTILES.ORG