During the busy season, when parties, events, weddings, festivals and so on have kicked into relatively high gear, tents are going out, coming back in and then going out again. While all of this activity is welcomed by tent rental companies, it does pressure them to ensure their inventories are up to the task, and the quieter winter season is the time most companies choose to address any issues. In some cases, this simply requires giving their tents a thorough cleaning. Other times repairs or even replacement are called for. And figuring out which of those two—repair or replacement—is needed isn’t as easy as one might think, says Michael Tharpe, southeast account manager for Rainier Industries Ltd.

Based in Tukwila, Wash., the company provides wall tents, yurts, retractable power screens and awnings, commercial tents and more, as well as offers cleaning, repair and replacement. According to Tharpe, many tent rental companies find determining whether to replace or repair challenging. As such, he says it can take “several conversations” to identify the issues in an effort to figure out which way to go.

Repair or replace?

“Generally, if repairs are more than 50% of the costs, it’s better to replace,” Tharpe says. “What should they look for? The condition of the vinyl has a lot to do with this. They should look at how stiff or abrasive the vinyl feels to the touch, the extent of the damage (panels vs. small patches) and damage in high-tension areas where reinforcement materials are separated.”

Tharpe is seeing an increasing number of tops being replaced due to long-term installations, which can damage vinyl thanks to excessive exposure to UV, wind and other abrasives. This fact, combined with rental companies simply not having the time or labor to clean and inspect their tops, has reduced the demand for vinyl repair.

For now, repairs are still coming in a little slower than pre-pandemic, “however, I anticipate that as the busy season slows down, we will see a much larger demand on tents getting repaired, especially for the next busy season,” Tharpe says.

Another factor affecting repairs is the uncertainty surrounding the future health of the U.S. economy and ongoing struggles with inflation in wages and materials, inspiring people to try and maintain their existing products longer rather than replacing them, says Paul Aumento, president of Creative Textile Solutions Ltd., a Halifax, N.S., Canada, manufacturer of value-added textile products such as awnings, banners, canopies, marine covers and more. The company also repairs commercial tent sidewalls and retail-style pop-up tents, as well as services and repairs other items.

If possible, repairs should be considered first, since this can be an economical way to increase a product’s life span, he says. But at some point, replacement becomes the only realistic, and cost-effective, option.

“Once a product reaches a point in its life span, a repair may not be economical,” Aumento explains. “For example, tents and tent sidewalls may be beyond repair due to degradation of the fabric, excessive staining and dirt, and generally poor appearance.”

Minor repairs such as pinholes or other tiny tears can likely be handled in-house, but large holes or rips, or damaged rings, plates and webbing probably require involving the manufacturer, says Jay Cole, operations manager for CCC Washers Inc. Headquartered in Rosholt, Wis., and co-located with tent provider Charnecke Tents Inc., the company makes three sizes of fully automatic, fully contained tent washers, two of which are portable.

“The age of the tent and the size can also be a determining factor if the tent can be repaired or not,” Cole adds. “Sometimes it is better to replace than to repair.”

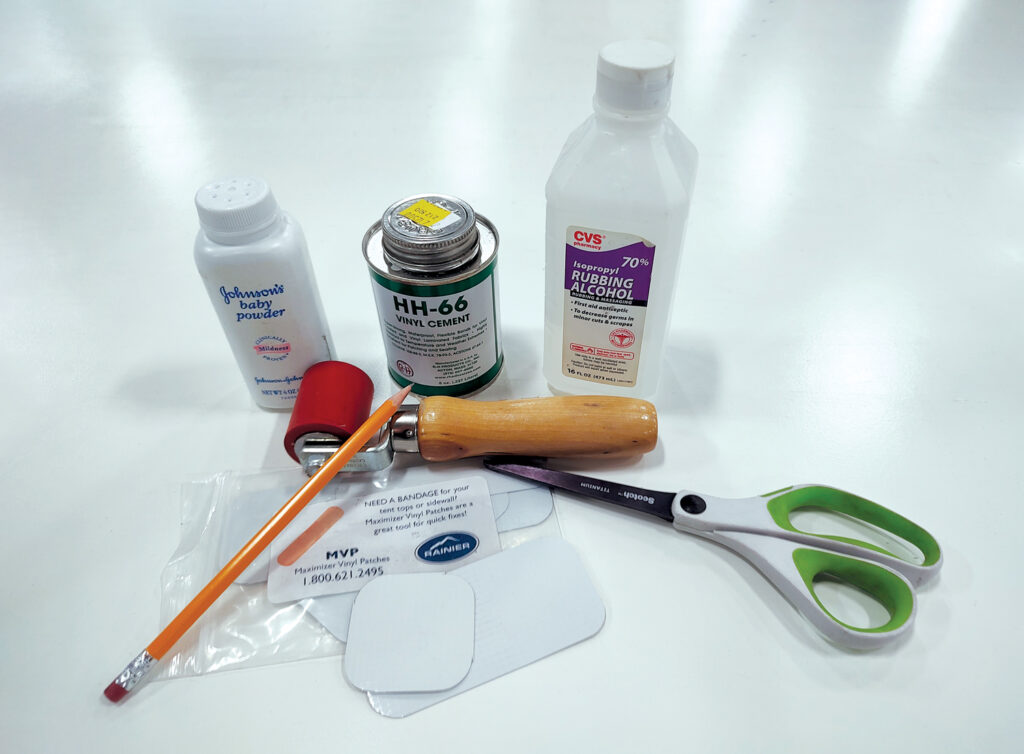

However, if taking a DIY approach to repairs, it’s important to have the right tools, Tharpe cautions.

“Use only HH-66 vinyl cement for making repairs, as this is specially formulated to work with vinyl products. If using a hot-air gun for making repairs, ensure you know what you’re doing so as to not damage the vinyl. Always practice and get used to the heat settings before attempting to repair using this process.”

Keeping them clean (and dry)

Fortunately, there’s no such confusion when it comes to cleaning—the need to do so is obvious. Steve Arendt is the owner/president of Teeco Solutions, a Fenton, Mo., provider of tent washing and drying machines and related products, like chemicals, tools and personal protective equipment (PPE) gear. He says that, ideally, tents should be cleaned in a washing machine after every other use, particularly when cleanliness is still on everyone’s minds—although this can vary by client.

“Companies that provide tenting for high-profile events must provide the cleanest tents possible and follow strict cleaning protocols,” he explains. “[But] often clients who need a tent for an industrial setting are less concerned about cleanliness. Justifying a strict cleaning routine may not make sense for companies serving more industrial clients.”

Cole says that at the end of the season, washing tents in a machine rather than by hand does a more thorough job of cleaning every part of the tent, especially the webbing and Velcro®. Because some dryers can be hard on tent vinyl, he prefers hanging tents up to dry using a pully system, conveyer or truss system.

But some dryers are easier on material than others, says Arendt.

“Drying tent tops requires special machinery,” he says. “Using the power of low-temperature, dehumidified air and a large rotating drum is the surest way to completely dry vinyl and all webbing associated with a tent top. Other style drying machines use high-powered wind to blow the water from the surface of flat roof panels. Vinyl dryers using this method offer the highest daily production, but will leave any webbing or keder sewn to the vinyl top damp.”

For washers, tumbler-style machines are effective at cleaning hard-to-remove stains, continues Arendt. Brush-style machines are useful for cleaning the flat pieces of roof vinyl.

Maintaining life span

Probably the best way to avoid a tough cleaning situation and extend a product’s useful life is not getting the tops dirty to begin with, Arendt says, adding that a careless approach to install and teardown can cause unnecessary soiling. Using drop cloths during both can keep tents cleaner and lasting longer.

Proper storage is also essential, says Tharpe. This means putting a clean, dry tent into a storage bag and placing this off the floor, since laying the bag on concrete can draw moisture into it, creating a mildew issue. Keeping the tent bagged between installations will further protect it, says Cole.

He also cautions installers to make sure the tent is dry and that debris like pine needles, leaves, balloons and so on have been removed before storing. One strategy CCC Washers uses is keeping a small blower in company trucks, especially useful during the fall, and blowing off the sections.

The importance of completely drying a tent before storing cannot be overstated. Putting a tent away wet can quickly ruin a tent top, allowing mold to grow within the tent’s folds, the by-products of which damages the vinyl, Arendt explains. Proper dying is “imperative” to how long a tent top will last.

“The lifetime performance of a tent is twofold,” says Arendt. “First, the fabric must withstand the test of Mother Nature. And in the process of doing so, it must remain clean enough to keep the customers happy. The constant attention to removing dirt, stains and soils ensures that discoloration and staining will not reduce the life span of a tent top.”

Pamela Mills-Senn is a freelance writer based in Seal Beach, Calif.

SIDEBAR: Fighting stains safely and effectively

Figuring out which chemicals to use or avoid can be “tricky,” says Steve Arendt, owner/president of Teeco Solutions. Some stains can only be removed from a tent top by an “aggressive” cleaning product whereas other more common soils and stains will respond to a safer, gentler agent.

“Solvents are excellent at removing many tough stains. However, most solvents harm the vinyl used for tent tops,” he says. “Chlorine and pH-modified products can harm vinyl, webbing, stitching and the person doing the cleaning. A cleaning agent with a near-neutral pH is the most likely choice to protect the vinyl, webbing and stitching found on a tent.”

(It’s also critical that protective gear is worn during the cleaning process and that those undertaking the task know how to read an MSDS, or Material Safety Data Sheet, Arendt says.)

Jay Cole, operations manager for CCC Washers Inc., says it’s best to avoid using degreasers, soaps that produce heavy suds and bleach, which will rapidly break down any plasticizers in the material. He advises those washing tents by hand that having a clean, dry and flat surface on which to lay them is essential. Arendt agrees this is a must.

“Cleaning a tent on a porous surface such as brushed concrete or asphalt will reduce the cleaning power of the bristles of the brush, the yarn on the mop, and the fibers of the cleaning pad on a floor polisher,” he explains.

He also recommends that when applying the cleaning chemical to the tent top, give it sufficient time to break the dirt away from the vinyl before starting the cleaning process. This will result in less scrubbing and less expenditure of effort.

As for these chemicals, Cole says to make sure they’re specifically designed for tent vinyl.

“They will clean the best and be the most economical,” he explains. “Use soft bristle brushes, buffers or mops to work the dirt and grime off the tents. And a word of caution about using pressure washers. If not used properly, they can damage the vinyl and threads with too much pressure and too hot of water. Best if used just for rinsing.”

When it comes to protecting vinyl, Michael Tharpe of Rainer Industries advises using non-petroleum-based cleaning products. Otherwise, the threads could yellow over time. “Never use Clorox® as your major cleaning liquid—this could damage the threads,” he adds.

TEXTILES.ORG

TEXTILES.ORG