53 feet tall.

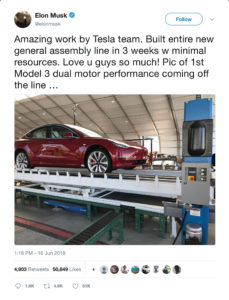

Tesla CEO Elon Musk shocked the automobile and tech worlds in June when he tweeted: “Needed another

general assembly line to reach 5k/week Model 3 production. A new building was impossible, so we built a giant tent in

two weeks.”

The “tent”—or more accurately, tensioned membrane structure—at Tesla’s Fremont, Calif., plant helped the company meet its second-quarter milestone of producing 5,000 Model 3 electric vehicles per week. While Tesla remained secretive with regard to the structure outside of a series of tweets from Musk, building permits referencing “Sprung” led many news sources to identify the building as a Sprung Fabric Structure.

Based in Calgary, Alberta, Canada, Sprung Instant Structures Ltd. fabricates tensioned membrane structures for applications ranging from military facilities to churches. Electric cars aren’t even the first high-tech vehicles associated with Sprung—the company built emergency landing buildings for the NASA Space Shuttle in the 1980s.

Sprung officials declined to comment on the structure to InTents due to a non-disclosure agreement. Wired magazine, however, described the structure as nearly 1,000 feet long, 150 feet wide and 53 feet tall. It reported that Tesla notified the city of the project in late May, filed its permits on June 11 and was up and running in about a week.

Sprung officials declined to comment on the structure to InTents due to a non-disclosure agreement. Wired magazine, however, described the structure as nearly 1,000 feet long, 150 feet wide and 53 feet tall. It reported that Tesla notified the city of the project in late May, filed its permits on June 11 and was up and running in about a week.

Mainstream media coverage included a lot of scoffing, although this may have had as much to do with the assembly line itself being “cobbled together with scraps lying around the brick-and-mortar plant,” according to Bloomberg, as it did the idea of manufacturing cars under a “tent.”

But Wired was a bit more open-mined, describing this approach as “an established, if uncommon, way for car makers to do one of two things: make fixes to vehicles that have gone through the regular assembly process, or build vehicles that come with special features, which are hard to integrate into an existing line.”

TEXTILES.ORG

TEXTILES.ORG