When there’s nowhere for a tented event to expand outward, multilevel structures help the festivities to go up.

by Pamela Mills-Senn

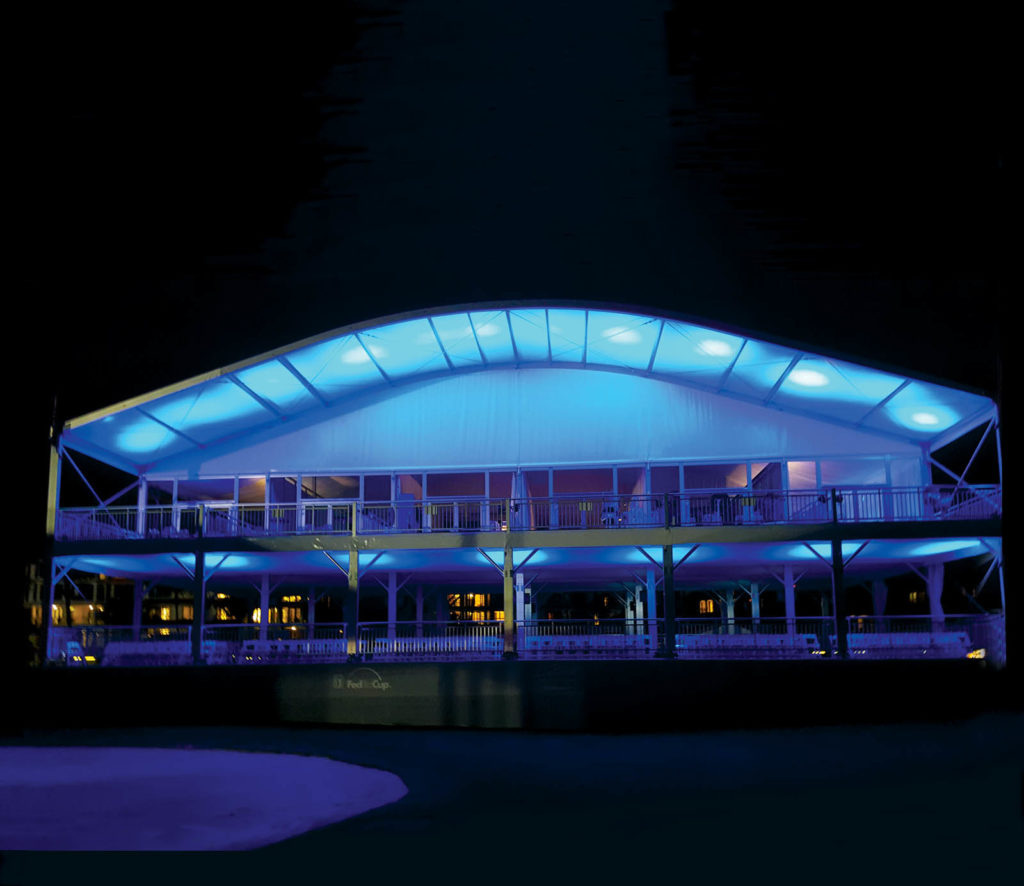

When Traube Tents and Structures entered the double-decker market this past spring, the Columbia, Ill.-based rental provider had exactly one contract for the two Losberger Emporium multistory structures it had added to its inventory. But owner Steve Traube knew that his client base wouldn’t let those shiny new structures hang around the warehouse. In their “inaugural year,” the structures have already been installed for multiple sporting, corporate and large fair and festival clients, Traube says.

“We have other potential clients who have shown interest in the past, and we expect to be able to rent to a few existing clients looking to take their events to the next level,” Traube says.

With their eye-catching profiles, multistory structures up the wow quotient for any event. The benefits these structures offer tent rental companies can also prove attention-getting.

Based in Kansas City, Kan., Liri Tent US supplies engineered clearspan structures and accessories, including two styles of double-decker tents. Because multistory structures are usually installed for large public gatherings such as sporting events and brand activations, they can give tent rental companies entry into markets previously out of reach, says Liri Tent US president Nate Brancato.

This was the case for Aztec/Shaffer LLC, says Ryan McMinn, CEO. The Houston, Texas-based company consists of Aztec Events & Tents, which provides party rental for corporate and private events, and Shaffer Sports & Events, which specializes in hospitality tents and temporary structures for major sporting events.

Shaffer has offered multilevel structures since 2012, including double-decker and triple-decker options with tiered seating and modular designs that allow for multiple configurations. For the 2015 Breeders’ Cup, the company designed and installed its first triple-decker. (According to McMinn, this was also the first use of such a structure in the United States.) Shaffer’s multistory structures appear in about 30 golf tournaments in North and South America annually.

“Almost every customer and venue is looking for new exterior and interior concepts,” says McMinn. “Having multilevel structures has allowed the company to expand into other sporting and non-sporting events and has added to our revenue base.”

Market growth

Demand for multistory structures is continuing to grow, says George Smith, president and CEO of Mahaffey Fabric Structures. Based in Memphis, Tenn., Mahaffey’s party and tent rental division serves the Mid-South, while its clearspan structure division travels nationally. Smith attributes the growing market to better engineering and design, which has made the structures easier to erect. He also credits the close quarters where many events take place. When space is tight, the only way to go bigger is to go up, he explains.

“Our two-story structures can be used with any manufacturer’s clearspan on the top floor,” Smith says. “It’s made in 5-by-5-meter blocks and can be arranged in numerous configurations.”

Smith says the company owns about 20,000 square feet of two-story structures. Mahaffey started carrying these products about 15 years ago, slowly increasing the inventory over the last 10 years.

“Clients like these tents because there are more branding opportunities,” Smith says. “Word of mouth and social media have generated great awareness. People see them for the first time and get excited about the possibilities. [These] have opened up new doors for us with traditional structures on the same venue.”

Return on investment (ROI) is generated fairly quickly, thanks to the price point and multiyear contracts, Smith adds. For example, Mahaffey’s first two-story rental was for the Buffalo Bills training camp at St. John Fisher College in Rochester, N.Y. The five-year contract called for a double-decker VIP tent, with food downstairs and viewing above. The tent was up for about a month each time.

Multistory structures allow event planners to think more imaginatively, create more space where real estate is limited, offer elevated viewing and impress their customers, all factors driving demand, says Jeff McInnes, director of sales for the US East Coast region, HTS Clearspan Structure Systems Inc.

Headquartered in Fort Lauderdale, Fla., the company supplies aluminum clearspan structures, ranging from 3-by-3-meter pagodas to larger, permanent code-compliant multistory structures. An industrial division makes warehouses and light commercial structures. The company’s two-level and three-level structures are used for hospitality suites and event venues such as the PGA, America’s Cup, festivals and music concerts. According to McInnes, concession outlets on the ground floor with VIP hospitality suites have becomes quite popular.

“It’s a growing sector,” says McInnes of multistory structures. “It’s easy to let your customers know going vertical is an option. We have found more often than not, the demand is there.”

Calculate before leaping

As compelling as the reasons are for adding multilevel structures to a rental inventory, they’re not right for every business. Because of the initial costs, it is imperative operators know beforehand that the structures have strong revenue-generating potential, rather than investing in them with the hope that demand will follow.

“We knew we had a sufficient number of jobs to make the necessary ROI,” McMinn says. “This can be a big barrier to entry for some rental businesses because you need to have the commitment first.”

There are other considerations, he adds. Multilevel structures require experienced, well-trained, “construction-oriented” crews and special safety precautions such as fall protection and railings. When crew members are working at double- and triple-decker heights, insurance and workers’ compensation will receive more scrutiny. Egress requirements increase, as do requirements related to the Americans with Disabilities Act (ADA), including the need for elevators.

“The equipment is more robust and requires more engineering than single-level structures as well as special racking, shipping and handling tools,” McMinn says. “We’re also seeing increased building and fire code enforcement across the country.”

Storage is another consideration. Because of their bulk and the number of parts, multilevel structures require additional space, even though they’re not likely to be rented as often as standard tents. It’s also imperative that crews are trained in operating heavy-duty forklifts, scissor lifts and cranes, Brancato says, adding that crew sizes will probably increase as well.

Despite these caveats, tent rental companies may want to give multilevel tents serious thought, because these structures can be fairly lucrative.

“The more you’re able to increase square footage, the more accessories and other supporting equipment can be offered by the rental company,” Brancato says. “The revenue density of the job is increased and over-profit dollars can follow.”

With a 6.8-meter side-height, Traube’s multilevel structures feature ground and mezzanine levels, both with a ceiling height of more than 10 feet. Traube rents glass and hard wall options along with multiple stair configurations for these structures—illustrating the additional upselling opportunities of high-end accessories.

Brancato anticipates the clamor for these structures to escalate. McInnes says the same. “The demand is sky high,” he says. “We’ve recently done some three-level structures here in the USA, and I only see more demand on the horizon. If they’re already coming, build it bigger and more will come.”

Pamela Mills-Senn is a Long Beach, Calif.-based freelance writer.

Multistory structures can help tent rental companies break into new markets and impress clients. But as lucrative as these structures can be, it makes sense to proceed with caution before adding this option to a rental inventory. Double- and triple-decker structures place new demands on equipment, personnel, installation and removal logistics, and the warehouse. And, if the market isn’t there, this expensive inventory will take up space in the warehouse instead of generating income.

What should tent rental companies be aware of before investing in multilevel structures?

Nate Brancato, president of Liri Tent US, Kansas City, Kan., suggests that tent rental owners and managers ask these questions:

- How well do I really understand my market, what buyers want and can afford, and what the competition is offering?

- What can my crews handle? Can I afford to invest in additional training?

- How frequently will the structure be rented? Multiple times annually? And for how long? Is there the potential for securing multiyear contracts?

“Make an honest assessment and create industry relationships with people you trust to give honest feedback about their experiences with inventory investments of this nature,” Brancato says.

What should tent rental companies expect from their suppliers?

Steve Traube, owner of Traube Tents and Structures, Columbia, Ill., says manufacturers should be able to provide all required documentation/certifications/evaluations along with client referrals. Query these sources about their experience with the product and the manufacturer, typical installation and removal times, and options and accessories to consider.

And make sure the manufacturer will provide a representative for the first install, says George Smith, president/CEO of Mahaffey Fabric Structures, Memphis, Tenn. “There are tricks you’ll need to learn with every two-story tent,” he says.

Multilevel structures will require re-evaluating every detail in the installation process.

Here’s some advice:

Double-deckers require bigger beams and the need for heavy equipment on-site. Further, more time and labor is consumed, so setting the price with your client is critical.

—Nate Brancato, president, Liri Tents US

Steps are expensive and tricky to build. It’s easy to undercharge for them. Just make sure you have the right number of steps. Make sure you do a thorough site inspection and know your elevation changes. Installs and dismantles are longer; make sure you get enough time. There are specialty parts and pieces you need to keep track of. Label and color-code everything.

—George Smith, president/CEO, Mahaffey Fabric Structures

TEXTILES.ORG

TEXTILES.ORG